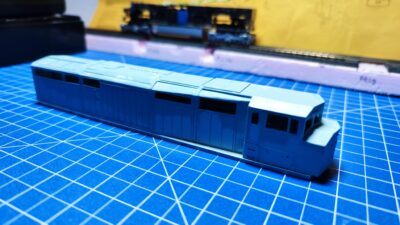

At the End of the last year, I got my hands on a KASLO Shops Distributing model of the C40-8M. While preparing the model for the build, I am also taking measures, comparing them to a drawing in the Model Railroader Magazine (from back when) and blocking out a 3D printable model of it.

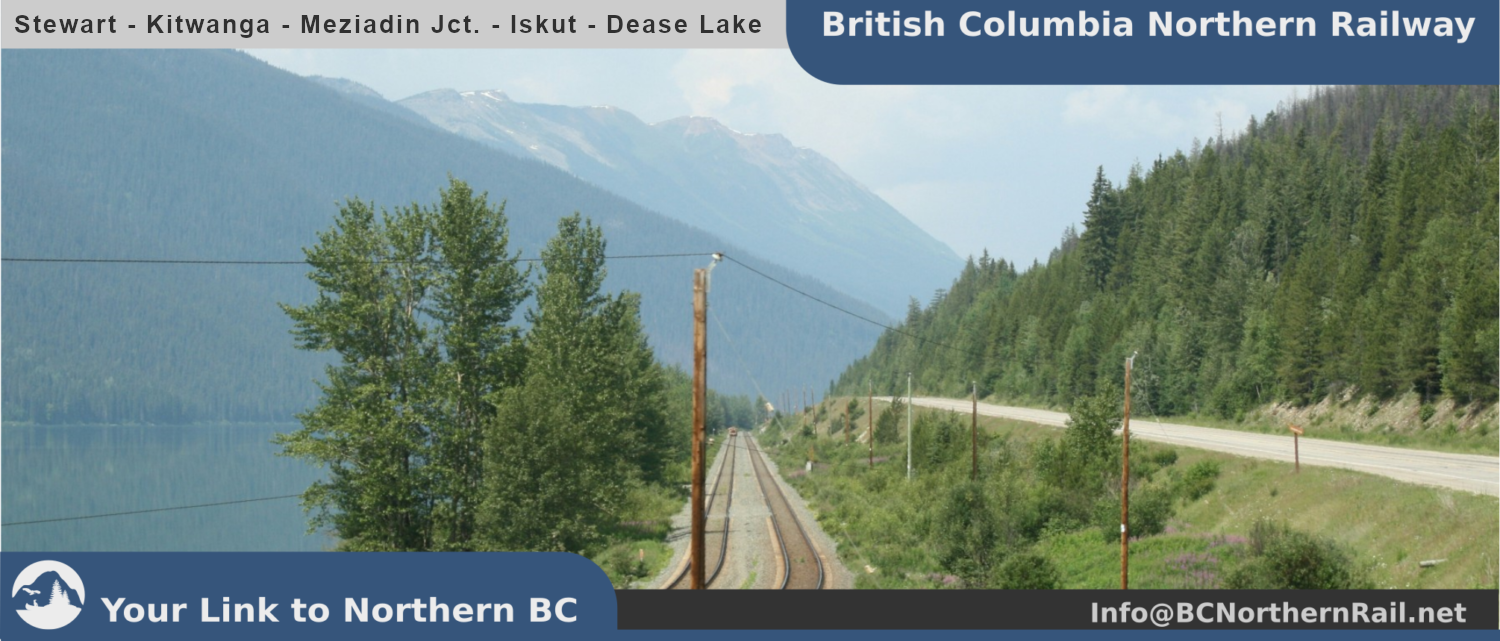

And for comparison some Photos

Here is a reference Model on TinkerCAD: https://www.tinkercad.com/things/iBp3PxTBH1l

And my remix (just to save the file): https://www.tinkercad.com/things/iIPKxLsrL6i

Dofasco HTC-Trucks

Today I started on the Dofasco HTC-Trucks for the model. I build the frame in Blender, using a scan from a Model Railroader drawing and the Trainiax drawings and reference photos by Michael Eby. Not all details are implemented yet, but its coming along. Renders below.

Obviously some detail is still missing, e.g. the brake detail and some bolts and bolsters, but I’ll get to that later. Stay tuned.

In the meantime, I had acquired a used donor Engine for the chassis. That wasn’t the smartest move for several reasons. Mainly because these model seem to be turning up predominantly on the UK market, which resulted in prohibitively high post-brexit import costs. But also turned out to be a variation with an older frame and a wrecked motor. Man. Needles to say, these motors predominantly turn up on the UK market too.

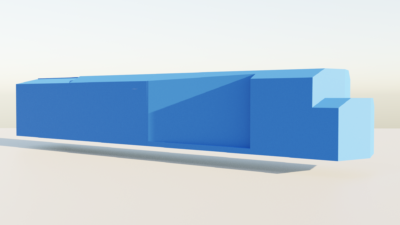

With all that being dang expensive, I decided to remotor the unit and design my own chassis. A preview can be seen below. It is currently printing, so more on that tomorrow or the day after.

The replacement Motor has yet to prove its viability, so this will be interesting. I designed a motor cradle (incorporated in the chassis above) and two spacers to fit over the flywheels that have correctly sized and spaced mounts for the drive shafts. So far the solution is not anywhere near precision machined flywheels, but hey, it’s a test, so why not. I can probably eliminate most of the vibrations by making the shaft adaptors much thinner.

I’ll keep you posted.